Nobody bats an eye these days when supply chain experts talk about how a semiconductor shortage impacts almost every product that requires sensors. The manufacturing of smartphones and tablets, IoT devices, and other types of IT hardware are all reeling from global supply chain disruptions and increasing costs for what is actually available.

One less talked about consequence is the impact on enterprise IT upgrade cycles. Companies are having to elongate typical asset lifecycles or turn to different asset classes to replace end-of-life mobile equipment. They are also looking for new creative workarounds, including purchasing used or remanufactured equipment and extending the life of existing devices with hardware warranties.

At the same time, the “Right to Repair” movement continues to gain momentum. The idea is to eliminate policies that bar third-party repairs and to give individuals and businesses easier, more affordable options to fix equipment and devices. Less than a year ago, President Biden signed an executive order that includes a section encouraging the Federal Trade Commission to prohibit manufacturer policies meant to keep repairs in-house only. Already, key players such as Apple and Microsoft have agreed to increase right-to-repair options by the end of 2022.

Now add in a growing societal push to extend the life of used devices. Enterprises are increasingly being held accountable by customers, employees and boards who expect businesses to be better stewards of the environment. The fact is that brands that embrace sustainability reap an array of benefits, including a more positive reputation, the ability to better attract and retain talent, and even the opportunity to reduce the costs of doing business.

The above factors – semiconductor shortages, rising costs, right-to-repair initiatives and environmental sustainability requirements – serve together as a serious catalyst for greater circular economy engagement within the enterprise community. With both economic factors and social drivers at play, businesses today are far more motivated than at any time in the past to proactively seek ways to share, reuse, repair, refurbish and recycle existing materials as long as possible.

A lack of education continues to stymie the circular economy

Our research at Blancco confirms that too many organizations are still wary when it comes to reusing or recycling devices containing data. Nearly three-quarters of outdated electronic equipment is not being recycled at large enterprises. In another survey, 93% of government IT employees in nine countries reported that their respective public sector organizations had defined plans to reduce the environmental impact caused by destroying IT equipment. Sadly, less than a quarter (21%) are actively implementing those plans.

Why? Organizations are reluctant to reuse or recycle devices because of security risks associated with the possible leakage of sensitive data contained on those devices. One key apprehension is that data will not be effectively eliminated at some point in the process when the used devices change custody, for example. If a business is not confident that its data is secure, it will turn to sub-optimal business practices, such as physical destruction or hoarding of devices, to prevent sensitive data from being recovered and used for malicious purposes.

A lack of education in regards to data security best practices is holding back progress. Organizations are simply not keeping up with the latest information, which is impacting their options in the context of sustainability. Specifically, they are basing their data security policies on obsolete physical destruction mandates, which are founded on outdated standards that have been accepted without question for far too long. Technologies and tools have advanced in recent years and now provide solid assurances to organizations, including tamper-proof audit documentation, that data erasure will meet data security compliance and best practices requirements.

Benefits of the circular economy

Decreasing the unnecessary physical destruction of devices is key to alleviating the growing e-waste crisis. More than 50 million metric tons of e-waste were produced worldwide in 2019 with only 17.4% of e-waste formally collected and recycled, according to UN’s Global E-waste Monitor 2020. Toxic substances, including mercury, brominated flame retardants (BFR). and chlorofluorocarbons (CFS), are found in many types of electronics and pose severe risk to human health.

Ramping up an organization’s engagement with the circular economy makes perfect financial sense as well. Doing so provides relief from the expense associated with destroying and replacing end-of-life devices. It also eliminates storage costs that come with the hoarding of old devices as a means to protect data they contain. It’s not unusual for an organization to spend more than 100,000 annually to store their useless IT hardware as a means to alleviate security or compliance risk.

Additionally, it is important to note that there’s a growing requirement for companies to report on their Environmental, Social and Governance (ESG) policies. For example, the Climate Corporate Accountability Act (CCAA) legislation in California would require US companies larger than 1B that do business in California to report all of the greenhouse gas emissions stemming from their direct operations. There is also a recent release by the SEC for US publicly traded companies to publish more climate related disclosures. When enterprises engage with the circular economy they can quantify this engagement – whether that is via the reuse of devices or recycling materials to build new devices – and use these metrics to exhibit movement on their ESG goals and show compliance. It’s a win for businesses and a win for the world’s efforts to protect our environment.

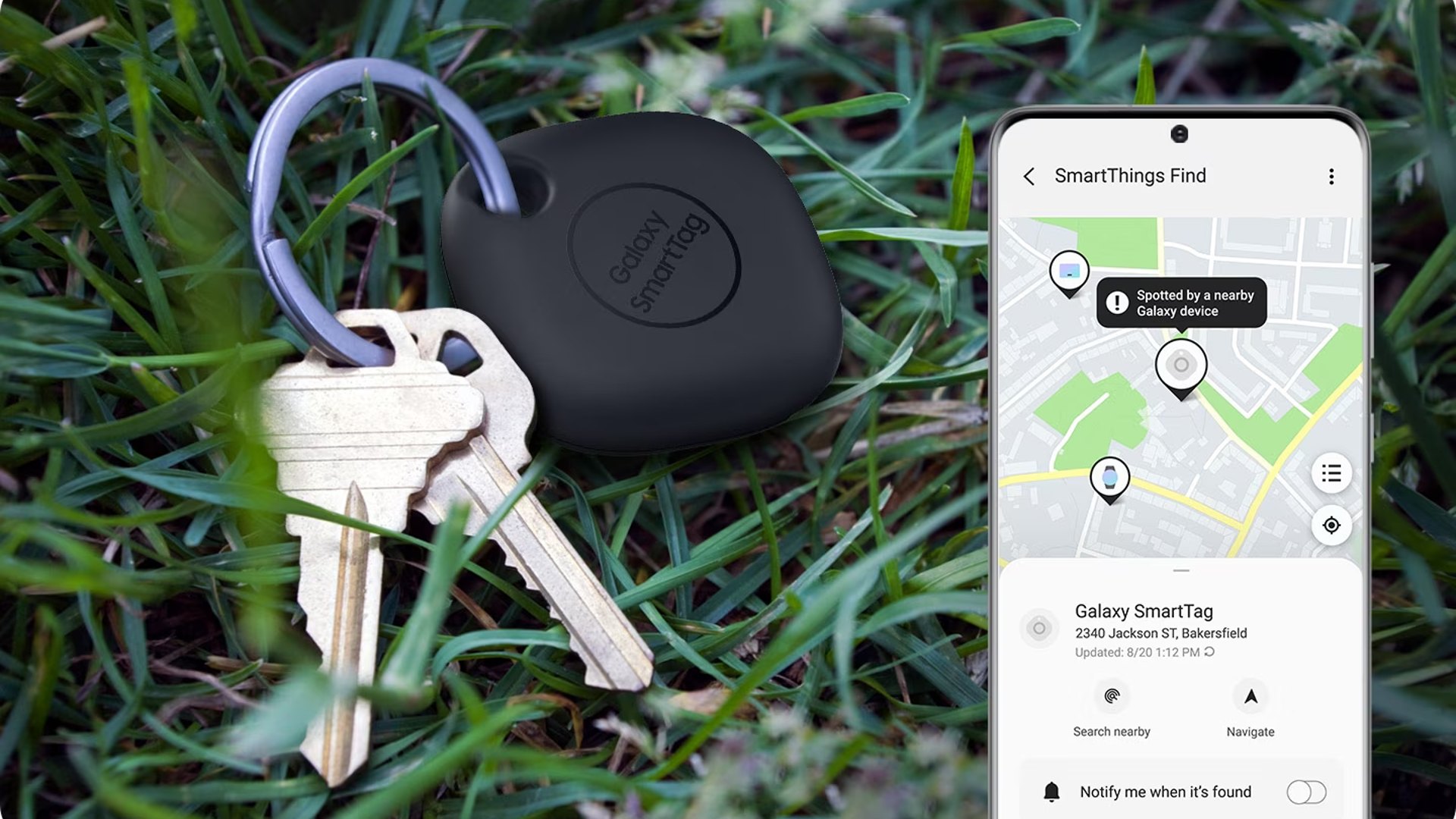

How the mobile ecosystem supports a more sustainable future

An increasing number of mobile ecosystem players – from carriers to manufacturers – are also taking steps to encourage customers to contribute to the circular economy. Lucrative carrier buyback offers for individual and business subscribers are helping meet growing secondary market demand and supply chain challenges. For example, upon the launch of iPhone 13, AT&T offered the public a staggering $ 1000 discount off the new device with a qualifying trade-in. At the same time, OEMs that face materials shortages are leveraging trade-ins to help prop up their businesses as they look to harvest the materials from used devices for reuse in the manufacture of new smartphones. These practices incentivize end-users to replace physical destruction of devices with data sanitization as part of responsible data management policies for their many mobile devices.

This Earth Day and beyond, enterprises and the tech community sit in a prime position to do more to increase the momentum of the growing circular economy. With customers and employees demanding environmental accountability and governments enacting legislation to reduce wastefulness in the electronics market, it’s imperative for the private sector to model sustainability from within and not just do the minimum required.

Russ Ernst is EVP of Products and Technology at Blancco, the standard in data erasure and mobile lifecycle solutions.

%20Wi-Fi%206%20White%20Paper%20Image.png#keepProtocol)